The Thread

Welcome to your home for sustainable living, from design inspiration and lifestyle tips to stories of sustainability and environmental impact.

Linen vs Cotton Sheets: Invest in Rest

February 12, 2024The linen vs. cotton sheets debate is one we’ve all experienced—but how do you know if you’ve made the right choice? Let’s explore two of our most coveted fabrics and see how they can revolutionize your sleep.

Celebrating the Importance of Biodiversity

Intersecting Worlds: Exploring the Convergence of Art, Design, and the Environment In this three-part series, we delve into the harmonious...

Read moreImprove Your Posture, Enhance Your Sleep

At the end of a long day, there’s nothing that your body craves more than an opportunity to decompress and...

Read moreTips For How to Get Better Sleep

Uncover the secret to a night of uninterrupted rest with these six essential sleeping tips and learn how to get...

Read moreAt Home with Robert McKinley

Welcome to At Home, a series where we step inside the unique dwellings of the most inspiring interior design minds....

Read moreLinen vs Cotton Sheets: Invest in Rest

The linen vs. cotton sheets debate is one we’ve all experienced—but how do you know if you’ve made the right...

Read moreDiana Yen's Artful Holiday Dessert: Hibiscus Po...

Savor the culinary masterpiece that is Hibiscus Poached Pears. Diana Yen, a visionary in the realms of food styling and...

Read moreAt Home with Emma Tuccillo

It’s time for another edition of At Home, our series that offers a glimpse into the intimate spaces of creative...

Read moreA Season of Gratitude

Gratitude is a life-hack, a super-power of sorts. It can help you retrain your brain to become a more positive...

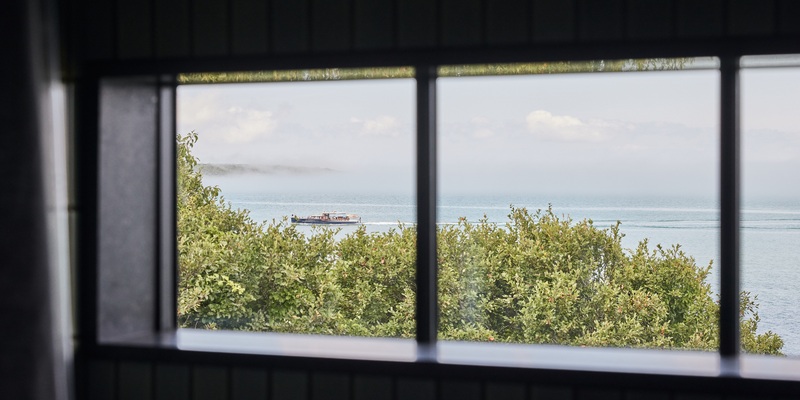

Read moreTravel Guide: Point Reyes Station

Embark on a restorative journey to a rustic town tucked between West Marin and Tomales Bay: Point Reyes Station. Explore...

Read moreAt Home with Lawren Howell

Being At Home with Lawren Howell was an exquisite exercise in expansive thought. Every angle curated with seasoned precision—flawlessly balancing...

Read moreGOTS Certified Organic vs. Oeko-Tex

We choose GOTS Certification because it is the highest standard in the world. When Coyuchi first introduced organic bedding and...

Read moreAt Home with Morgan Marie Jones

We were invited into the Brooklyn home of Morgan Marie Jones, the founder of boutique agency Take Out. Join us...

Read moreViewing 12 of 84